Rapid prototyping

Sand casting as rapid prototyping process

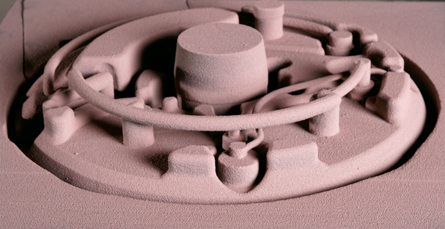

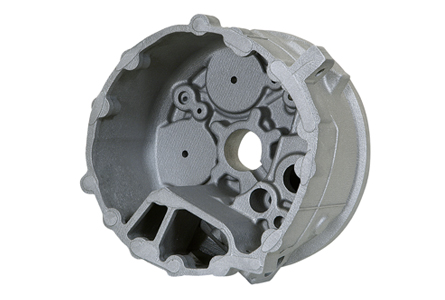

For very small quantities and high complexity, moulds can be made entirely of core material. These core blocks can also be created in the cold box process as well as laser-printed.

Very high levels of design freedom and surface quality distinguish this process. This process is preferred in prototype quantities of less than 5 pieces, as the amortisation of tools is eliminated.

With regard to RP production, this process offers the possibility to generate any development step directly from the 3D data set. This provides the designer with fast feedback about the effectiveness of his design changes, as well as savings from otherwise conventional model adjustments.